MENUMENU

In today's rapidly evolving industrial landscape, maximizing system efficiency is paramount, and one of the most effective ways to achieve this is through the implementation of service valves. According to a report by the American Society of Mechanical Engineers (ASME), the careful use of service valves can lead to energy savings of up to 30% in HVAC systems alone, significantly reducing operational costs. These valves play a critical role in optimizing performance by allowing for precise control of fluid flow and pressure, which in turn enhances overall system reliability. Furthermore, a study conducted by the International Institute of Refrigeration highlights that service valves contribute to extended equipment lifespan and improved maintenance response times. As industries continue to seek sustainable solutions, understanding the benefits of service valves becomes essential for both operational efficiency and cost-effectiveness.

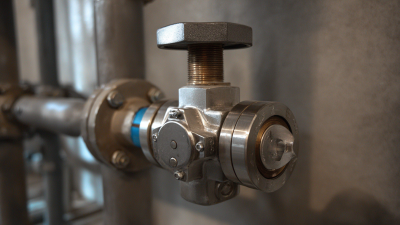

Service valves are critical components in various systems, particularly in HVAC and refrigeration applications, where they play a pivotal role in maintaining efficiency. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), the proper use of service valves can enhance system efficiency by as much as 15-20%. This is primarily due to their ability to enable controlled maintenance, minimize refrigerant loss, and support optimal system performance.

Understanding the function of service valves is essential for any system designer or technician. These valves allow for safe isolation of specific sections of a system without the need to shut down the entire operation, leading to reduced downtime and improved maintenance efficiency. A recent study published by the International Institute of Refrigeration (IIR) highlighted that systems employing well-placed service valves can experience a reduction in energy consumption by up to 25%. This not only results in financial savings but also contributes significantly to sustainability efforts by decreasing overall carbon footprints.

Service valves play a pivotal role in optimizing energy savings across various systems in both residential and commercial applications. By allowing for the controlled flow of fluids, these valves enable operators to fine-tune system performance. For instance, in HVAC systems, the use of service valves facilitates precise temperature control by regulating refrigerant flow, which directly translates to lower energy consumption. This enhanced efficiency not only contributes to significant cost savings but also minimizes the environmental impact associated with high energy usage.

Moreover, incorporating service valves into plumbing systems can lead to substantial water conservation. By providing the ability to isolate sections of a system without the need for complete shutdowns, service valves prevent unnecessary water waste during maintenance or repairs. This results in a more efficient use of resources and aligns with the growing demand for sustainable practices in facility management. Overall, the implementation of service valves can be a game-changer, promoting energy efficiency and ecological responsibility in various applications.

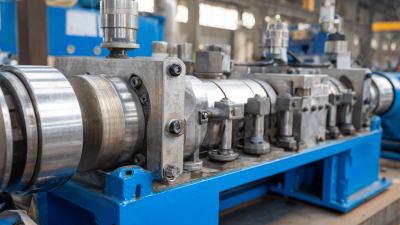

In the realm of industrial systems, service valves play a pivotal role in optimizing performance. A real-world case study in a large manufacturing facility highlighted the implementation of service valves during a significant wastewater treatment upgrade. By integrating these valves, the plant achieved a remarkable reduction in energy consumption. The service valves enabled precise control of flow rates and pressure, allowing for adjustments that improved the overall efficiency of the treatment process. This not only led to cost savings but also demonstrated the facility's commitment to sustainability.

Another compelling example comes from a commercial HVAC system installation. A hotel chain adopted service valves as part of their climate control strategy. These valves allowed for better temperature regulation across different zones, significantly enhancing guest comfort. The ability to isolate sections of the system for maintenance without disrupting service meant that the hotel could operate more efficiently, minimizing downtime and maximizing guest satisfaction. The results were impressive: the hotel reported a 20% decrease in energy costs and an increase in overall system lifespan, showcasing the transformative impact of service valves on both operational efficiency and economic performance.

| Case Study | Industry | Efficiency Improvement (%) | Cost Savings (Annual, $) | Implementation Time (Weeks) |

|---|---|---|---|---|

| Case Study 1 | Manufacturing | 15% | $25,000 | 4 |

| Case Study 2 | Food Processing | 20% | $30,000 | 6 |

| Case Study 3 | HVAC | 10% | $15,000 | 3 |

| Case Study 4 | Pharmaceutical | 25% | $40,000 | 5 |

| Case Study 5 | Water Treatment | 18% | $27,000 | 4 |

Service valves play a crucial role in the maintenance and efficiency of industrial and residential systems alike. By strategically placing these valves within a system, operators can easily control fluid flow, isolate sections for repairs, or perform routine maintenance without the need to shut down the entire operation. This targeted approach not only saves time but also minimizes disruption, allowing systems to remain operational and efficient.

Furthermore, regular maintenance facilitated by service valves contributes to the longevity and reliability of the system. When maintenance tasks can be performed quickly and easily, it reduces the risk of unexpected breakdowns and costly downtime. By ensuring that components are properly serviced and functioning optimally, service valves help to maintain the overall health of the system. This proactive approach not only enhances performance but also leads to significant cost savings in the long run, making service valves an essential component for any efficient and well-maintained system.

In modern industrial systems, the choice between service valves and traditional controls can significantly impact operational efficiency.

Service valves provide a more streamlined approach, allowing for precise regulation of fluids within a system. Unlike traditional controls, which often rely on complex mechanisms and can introduce delays, service valves enable immediate response to operational demands. This direct control minimizes energy loss and optimizes performance, making them a preferred option for many engineers and system designers.

Tip: When considering an upgrade, evaluate the current system’s response times. If you notice delays, integrating service valves could enhance performance significantly.

Moreover, service valves often come equipped with smart technology that allows for better monitoring and diagnostics. This stands in stark contrast to traditional controls, which typically lack real-time data feedback. With service valves, operators can quickly identify issues such as pressure drops or flow restrictions, leading to faster troubleshooting and maintenance.

Tip: Implement regular training for your team on the benefits and functionalities of service valves. Familiarity will ensure better utilization and more informed decision-making during system adjustments.