MENUMENU

In today's industrial landscape, selecting the appropriate high pressure valve is critical for ensuring operational efficiency and safety across various applications. According to a recent report by Grand View Research, the global valve market is expected to reach USD 100.3 billion by 2025, with a significant portion attributed to the demand for high pressure valves in sectors such as oil and gas, chemical processing, and power generation. These valves play a pivotal role in managing the flow of fluids under high pressure conditions, thus safeguarding the integrity of systems. However, the diverse range of options available can make the selection process daunting. Factors such as material compatibility, pressure ratings, and industry-specific standards must all be carefully considered to meet regulatory compliance and operational demands.

In this guide, we will explore essential criteria and best practices for choosing the right high pressure valve to meet your industry's specific needs.

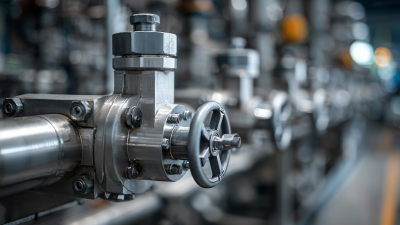

When selecting the appropriate high-pressure valve for industrial applications, it is crucial to understand the various types available and their specific functionalities. High-pressure valves, including ball valves, check valves, gate valves, and globe valves, each cater to distinct operational demands. For instance, ball valves are renowned for their quick shut-off capabilities, making them ideal for high-pressure systems requiring rapid response. In contrast, gate valves are typically utilized for on/off service in applications where minimal pressure drop is preferred.

The industrial valve market is projected to experience significant growth, with an estimated value reaching $121.67 billion by 2024. Key factors driving this expansion include increasing demand for high-pressure systems across sectors such as energy, marine, and food processing, where high-pressure homogenization is vital for maintaining product quality and safety. As industries continue to innovate, understanding the technical requirements—such as maximum operating pressure, valve material, and leakage tolerance—becomes paramount for ensuring efficiency and safety in operations.

When selecting the right high pressure valve for specific industry requirements, evaluating material compatibility is crucial, especially in diverse environments. Different applications expose valves to varied temperatures, pressures, and corrosive substances, necessitating careful consideration of the materials used in the valve construction. For instance, in chemical processing industries, valves made from stainless steel or special alloys may be needed to withstand aggressive chemicals, whereas less corrosive environments might allow for the use of standard carbon steel.

Furthermore, the operating environment plays a significant role in material selection. In high-temperature applications, materials with good thermal stability, such as nickel-based alloys, are preferred to prevent deformation and ensure longevity. In contrast, environments that involve cryogenic temperatures require materials that retain their strength and rigidity under low-temperature conditions, such as certain grades of stainless steel. Assessing factors such as pressure ratings, temperature limits, and the nature of the fluids being handled will guide engineers in choosing the most suitable materials, thereby optimizing performance and safety in high-pressure valve applications.

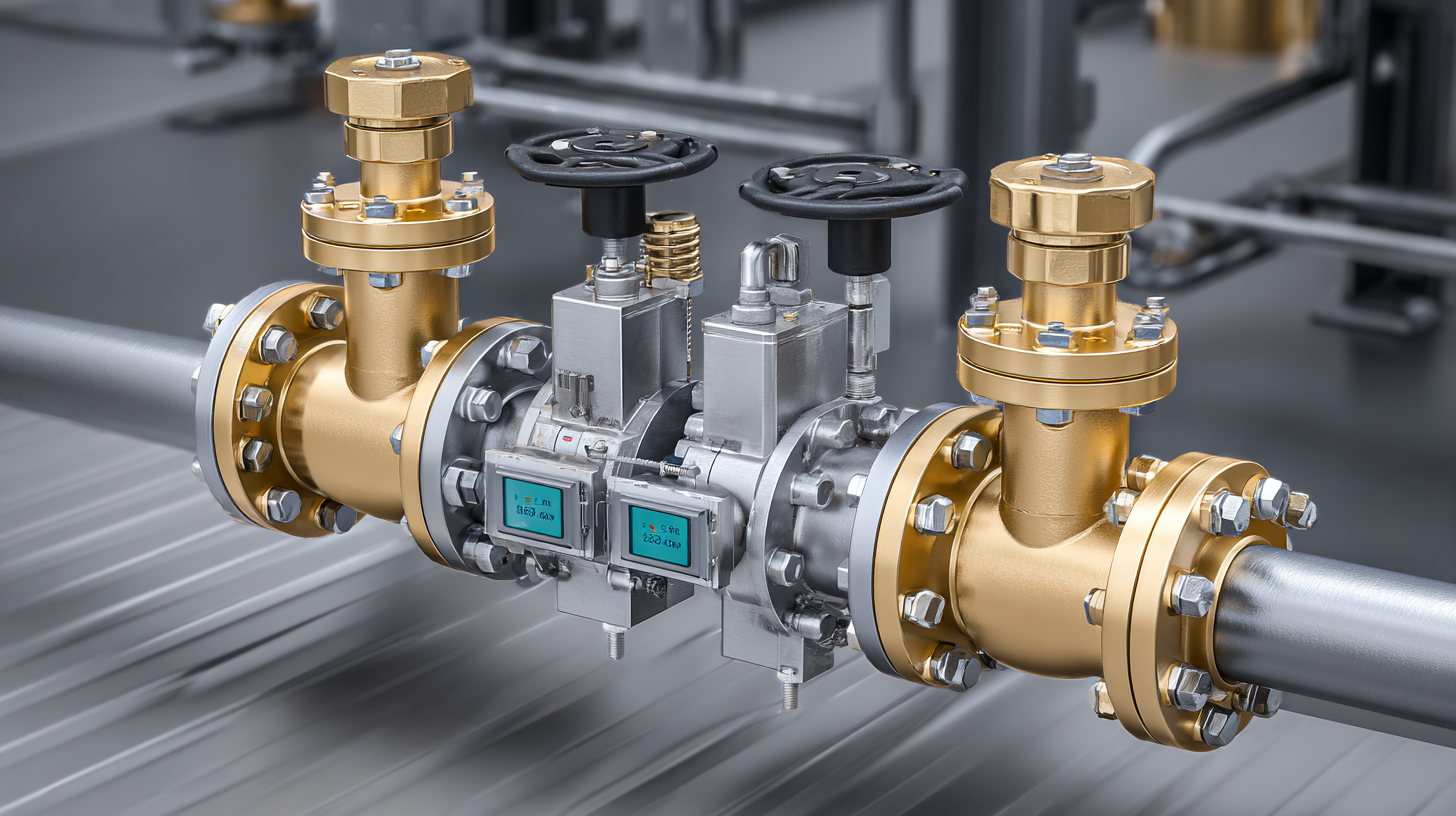

When selecting a high-pressure valve, understanding pressure ratings and operational limits is crucial for ensuring both safety and efficiency within industrial applications. Pressure ratings indicate the maximum pressure a valve can handle under specific conditions without risking failure. Each valve type comes with a manufacturer-defined pressure rating, which must align with the maximum pressure experienced in your system. It's essential to consult industry standards and guidelines to choose a valve that not only meets these requirements but also accommodates any potential pressure fluctuations in your process.

Additionally, operational limits encompass factors such as temperature, flow rate, and the specific medium being transported through the valve. For example, high temperatures may affect the material integrity, thereby altering the expected performance of the valve. Operating conditions such as cyclic stress or corrosive environments can also impact longevity and reliability. Therefore, comprehensive evaluation of these parameters ensures that the selected valve will function within its safe operational limits, preventing hazards such as leaks or catastrophic failures in high-pressure systems.

| Valve Type | Pressure Rating (PSI) | Temperature Range (°F) | Material | Common Applications |

|---|---|---|---|---|

| Ball Valve | 5000 | -20 to 300 | Stainless Steel | Oil & Gas, Chemical Processing |

| Gate Valve | 6000 | -50 to 400 | Carbon Steel | Water Supply, Oil Pipelines |

| Globe Valve | 3000 | -40 to 450 | Brass | Steam, HVAC Systems |

| Check Valve | 4000 | -10 to 250 | PVC | Water Treatment, Chemical Processing |

| Butterfly Valve | 1500 | 0 to 200 | Aluminum | Water Supply, Wastewater Management |

When selecting the right high pressure valve for your industry, it's crucial to assess the

relevant industry standards and certifications

to ensure reliability and performance. The ISA-75 Series of Standards is a prominent guide

for control valve design, testing, and performance. Following these standards not only enhances safety

but also promotes efficiency in various industrial applications. Familiarizing yourself with these guidelines

can significantly influence your choice of high pressure valves, especially in sectors where safety and

reliability are paramount.

Tips: Always verify that the valves you consider comply with established

industry standards. This includes looking for certifications that ensure the valves have been rigorously tested

for safety and performance. Engage with manufacturers or suppliers who are knowledgeable about these standards,

as they can offer valuable insights during your selection process.

In addition, integrating a model-based systems engineering (MBSE) approach during the early design phases can

further ensure that the chosen valves will meet specific operational requirements. By applying a multidisciplinary

framework that includes safety assessments, you can make more informed decisions tailored to your unique

industry needs, thereby enhancing both safety and operational efficacy.

When selecting a high pressure valve, conducting a thorough cost-benefit analysis is key to ensuring both quality and budget are effectively balanced. According to a report by MarketsandMarkets, the global valves market is projected to reach USD 90 billion by 2025, driven by industrial automation and the increasing need for efficient process control. This surge emphasizes the importance of investing in high-quality valves that not only minimize operational downtime but also enhance overall process efficiency.

By examining lifecycle costs, including maintenance and operational efficiency, industries can better understand the long-term benefits of higher-quality valves. For instance, a well-manufactured high pressure valve can reduce the frequency of replacements, leading to significant savings on both procurement and labor costs over time. A study by ARC Advisory Group indicates that organizations often save up to 20% in maintenance costs by investing in superior valve technology upfront. Hence, while budget constraints are important, prioritizing quality in high pressure valve procurement can yield substantial long-term benefits.