MENUMENU

In today's fast-paced industrial landscape, efficient fluid management is paramount for operational success, and check valves play a crucial role in this equation. A report by the Global Check Valve Market states that the check valve industry is anticipated to reach over $7 billion by 2026, driven by the increasing demand for fluid control in sectors such as oil and gas, water treatment, and manufacturing. Choosing the right check valve is not merely a technical decision; it directly impacts system efficiency, safety, and maintenance costs. With various types and specifications available, it is essential for industry professionals to understand the key factors that influence check valve performance. This guide will explore critical considerations in selecting the optimal check valve solution for your specific industry needs, ensuring enhanced fluid management and overall system reliability.

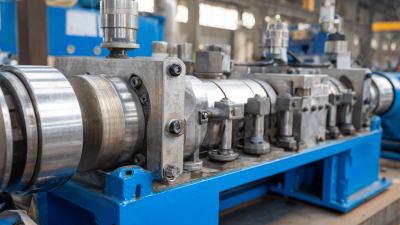

When selecting a check valve for your industry, understanding the specific fluid applications is crucial. Check valves come in various types, each designed to handle different fluids and operating conditions. For example, ball check valves are ideal for applications involving clean liquids and gases, as they offer low pressure drop and reliable sealing.

On the other hand, swing check valves, which use a disc to block reverse flow, are suitable for large pipes and higher flow rates, making them a popular choice in water and wastewater management.

On the other hand, swing check valves, which use a disc to block reverse flow, are suitable for large pipes and higher flow rates, making them a popular choice in water and wastewater management.

Moreover, there are specialized check valves like spring-loaded check valves that excel in applications requiring quick and responsive flow control. These valves are designed to close quickly when backflow occurs, enhancing system efficiency and protecting sensitive equipment. Understanding the nuances of each type and their specific suitability for various fluids—whether corrosive chemicals, high-viscosity substances, or sanitary fluids—will allow industries to optimize fluid management and ensure system reliability. By carefully evaluating the characteristics and requirements of your application, you can select the right check valve that enhances performance and extends the lifespan of your fluid handling system.

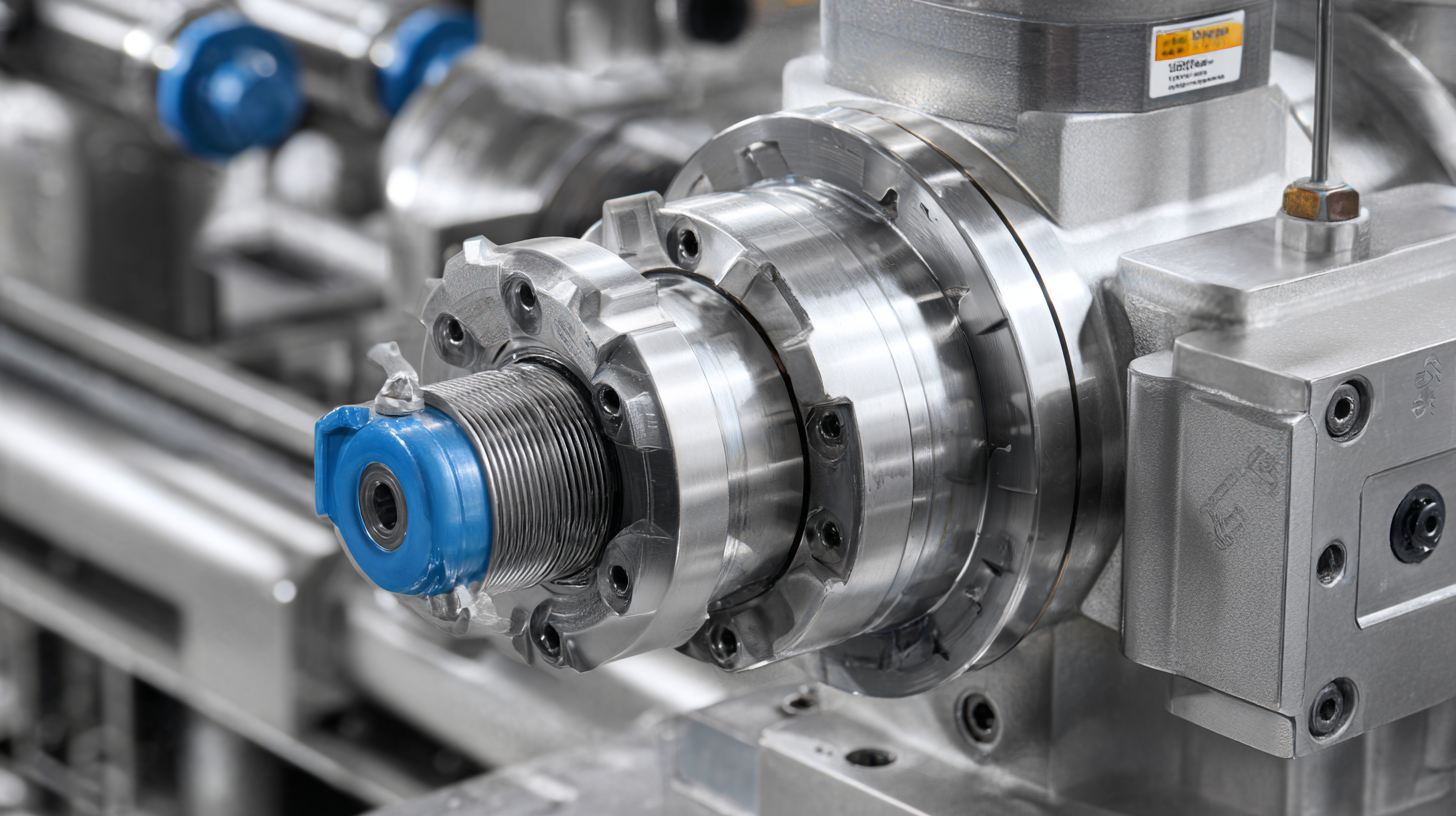

Selecting the right check valve for optimal fluid management hinges significantly on material selection, which directly impacts performance and longevity. According to a 2022 report by the Fluid Control Association, about 40% of check valve failures can be attributed to inappropriate material choices for specific fluid environments. For instance, materials like stainless steel are ideal for corrosive environments due to their resistance to oxidation and rust, while PVC is often favored in chemical applications where lightweight and cost-effectiveness are essential.

Moreover, the longevity of a check valve is critically influenced by thermal and pressure considerations associated with the chosen material. A study by the American Society of Mechanical Engineers highlighted that valves made from high-temperature alloys can withstand extreme conditions up to 1,200°F, thereby increasing their lifespan by 30% compared to standard materials under similar conditions. Therefore, industries managing diverse fluids must prioritize the analysis of material properties and their compatibility with process requirements to enhance not just the immediate functionality of check valves but also ensure their durability over time.

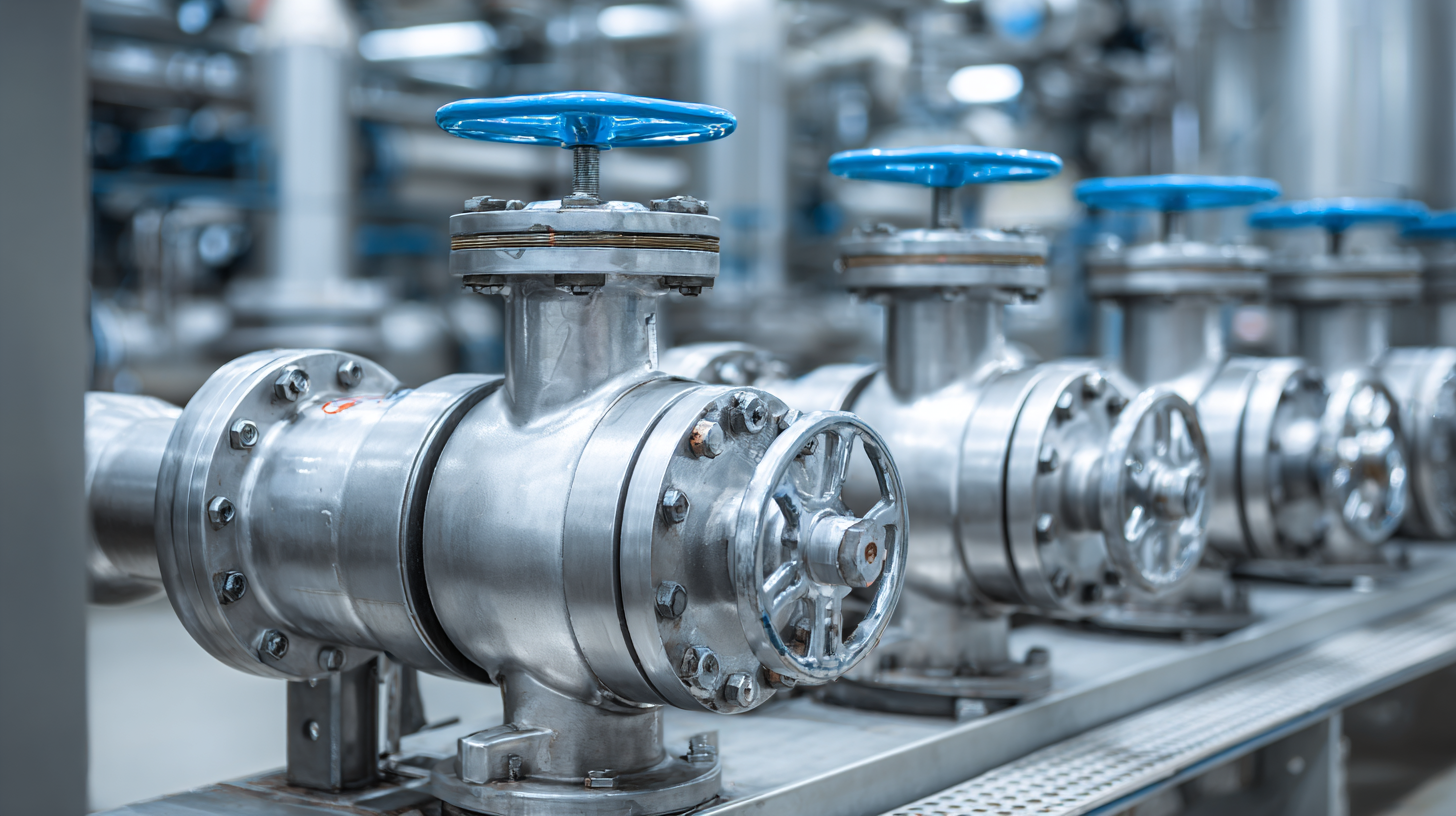

When selecting a check valve for effective fluid management, understanding the differences between spring-loaded and gravity check valves is crucial. Spring-loaded check valves utilize a spring mechanism to maintain a tight seal when there is no flow, which allows for quicker responses in systems where pressure changes can be rapid. Their design provides reliability in maintaining one-way flow and preventing backflow, making them ideal for applications that require precise fluid control, such as in chemical processing or water supply systems.

On the other hand, gravity check valves rely on the weight of the valve disc to achieve closure. These valves are typically more straightforward in design and are best suited for applications where the flow direction is predictable and constant, such as drainage systems or wastewater management. While gravity check valves may be less effective in maintaining a seal under high-pressure conditions, they are often more cost-effective and can handle larger flow volumes. Understanding these characteristics helps industries choose the right valve type for their specific fluid management needs, ensuring optimal operation and preventing costly equipment failures.

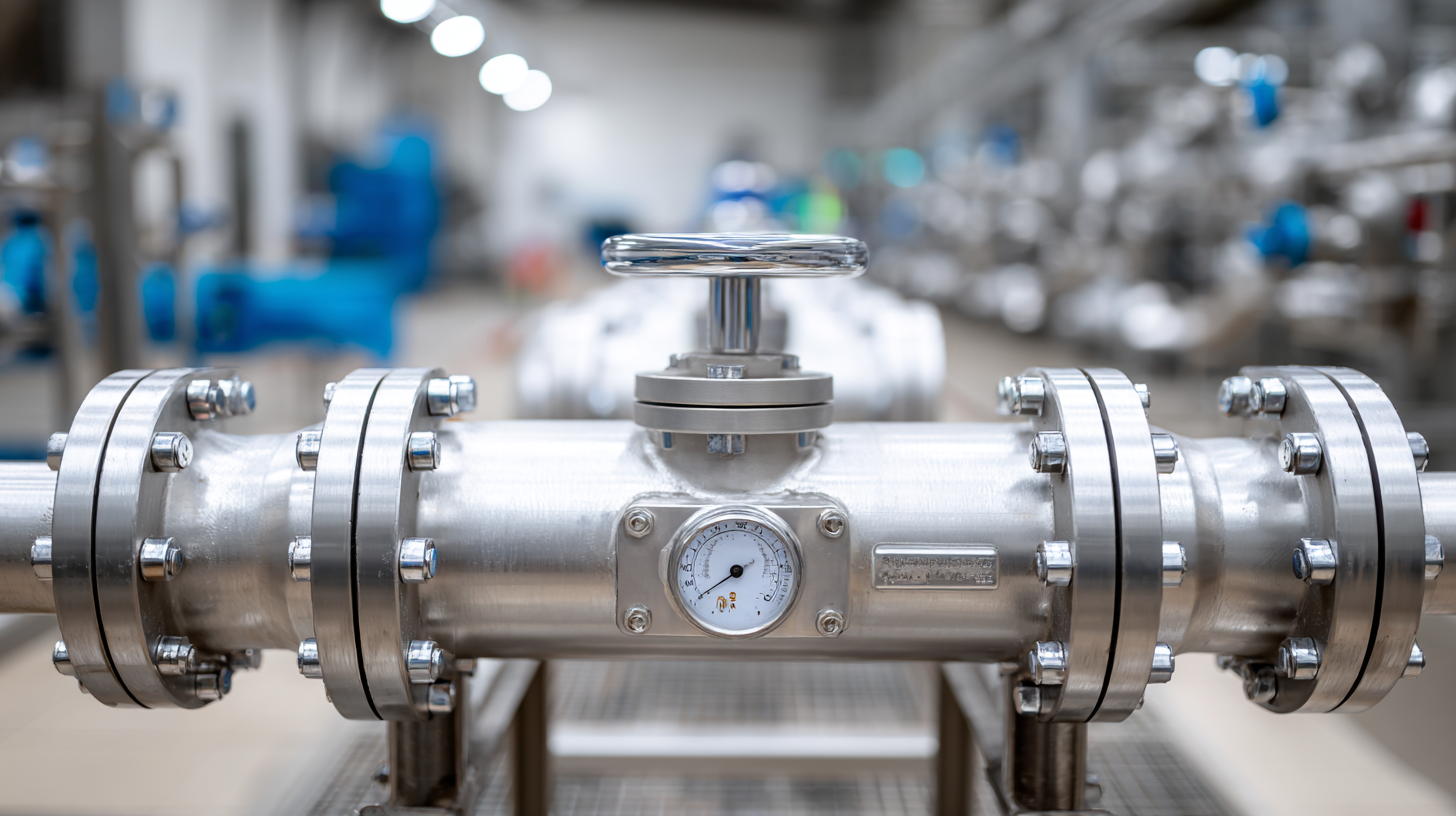

When selecting the right check valve for effective fluid management, understanding key performance metrics is crucial. One significant metric is the flow coefficient (Cv), which measures the valve’s capacity to allow fluid to flow through it. According to a recent industry report by the Fluid Control Institute, valves with a higher Cv offer lower flow resistance and contribute to improved energy efficiency—up to 15% in some systems. This efficiency not only reduces operational costs but also minimizes wear on downstream equipment.

Another critical parameter is the valve's cracking pressure. The cracking pressure is the minimum upstream pressure needed to open the valve, which can significantly impact the system's reliability. Research shows that check valves with appropriately low cracking pressures can prevent backflow effectively, resulting in reduced downtime and maintenance costs. A study published in the Journal of Fluid Engineering highlighted that improper cracking pressure settings could lead to increased leakage rates, with some industries experiencing up to a 20% loss in fluid integrity over time. Thus, ensuring both high Cv values and optimal cracking pressure is essential for maintaining an efficient and reliable fluid management system in any industry.

When selecting a check valve for optimal fluid management, industry-specific standards and regulations play a crucial role in ensuring compliance and operational efficiency.

Different industries, from pharmaceuticals to oil and gas, often have specific codes that govern the materials and performance characteristics of check valves.

For example, in the pharmaceutical sector, valves must be constructed from materials that meet stringent sanitary requirements, ensuring no contamination occurs during the fluid transfer process. Adhering to these regulations not only protects public health but also minimizes the risk of product recalls and liability issues.

Moreover, understanding the regulatory landscape can help streamline the selection process.

Many industries are governed by organizations such as the American National Standards Institute (ANSI) or the American Society of Mechanical Engineers (ASME), which provide guidelines for pressure ratings, temperature limits, and installation practices.

Familiarity with these standards allows engineers to choose check valves that not only fit their operational needs but also satisfy regulatory requirements. This strategic alignment not only enhances safety and reliability in fluid systems but also facilitates smoother inspections and audits, ultimately contributing to a more efficient operation.