MENUMENU

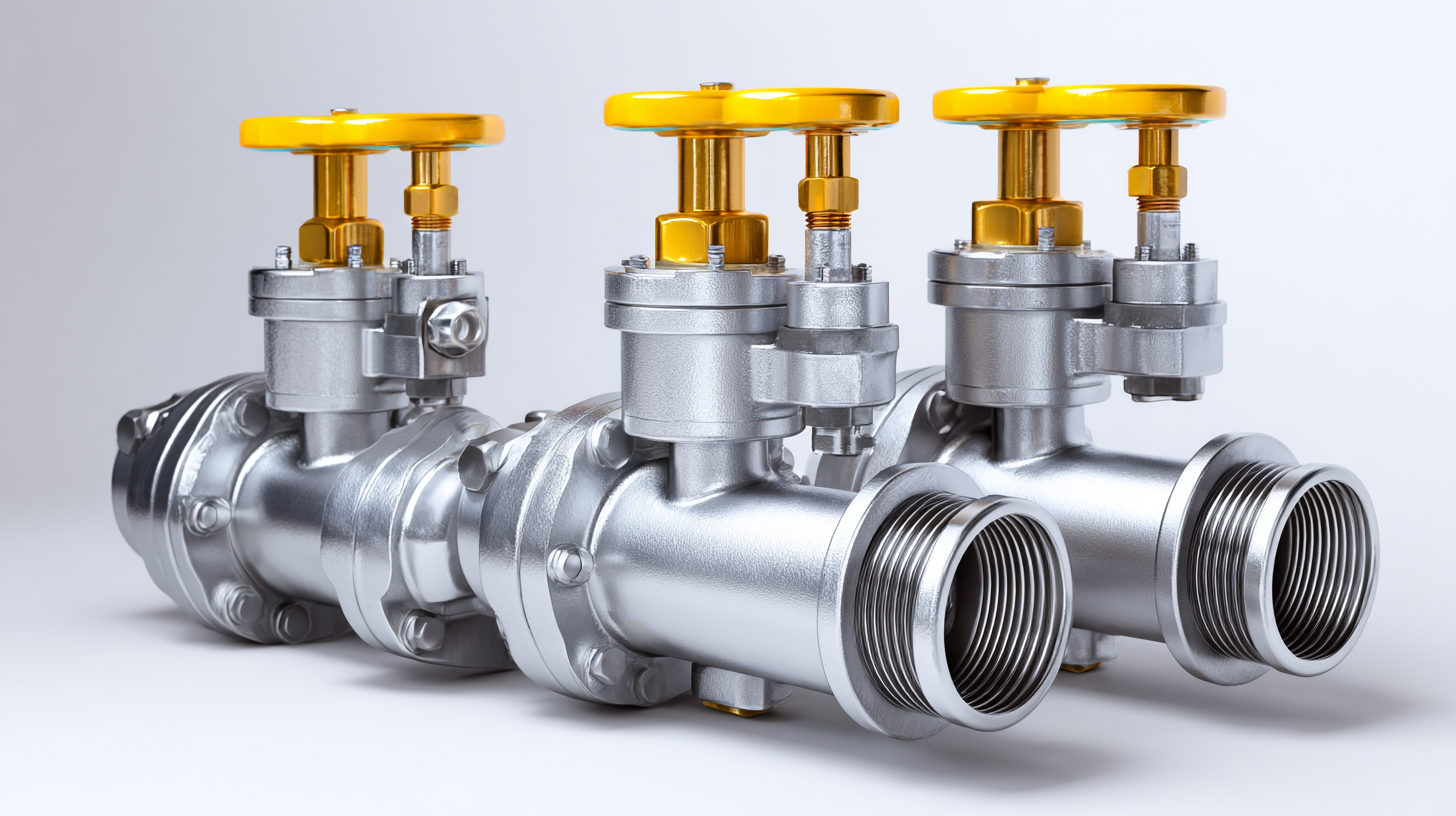

When it comes to maintaining the efficiency and safety of your industrial operations, selecting the right service valve is crucial. These essential components play a pivotal role in controlling the flow of fluids and gases, making their performance directly impact your business's productivity and reliability. However, with so many options available in the market, sourcing the best service valve can be a daunting task. To aid you in this critical decision-making process, we’ve compiled five essential tips that focus on comparison strategies, ensuring you choose the ideal service valve tailored to your specific needs. By understanding key factors such as material compatibility, pressure ratings, and operational efficiency, you can streamline your selection process and enhance your overall operational effectiveness. Let’s dive into these tips to help you make informed choices for your business.

When sourcing service valves for your business, it's crucial to understand the various types available and their specific applications. Service valves come in different forms—each designed to meet specific operational needs across industries. For example, pressure relief valves are essential in critical gas applications to prevent overpressure, while safety valves in oil wells play a vital role in preventing uncontrolled flow, ensuring both safety and efficiency in well completions.

In the rapidly evolving landscape of valve technology, advancements such as hydrogen valves are becoming pivotal in the shift towards cleaner energy solutions. These valves are designed to handle the unique requirements of hydrogen applications, which are integral to reducing carbon footprints. Additionally, the integration of automated actuators in water and wastewater applications highlights their importance in improving operational efficiency. Understanding these nuances ensures that businesses can choose the right service valves that not only enhance performance but also align with industry trends and safety standards.

When selecting service valves for your business, it's crucial to consider several key factors that can significantly impact the efficiency and reliability of your operations. According to a recent report by Global Market Insights, the service valve market is expected to reach $12 billion by 2026, indicating a growing demand for high-quality valves across various industries. This presents an opportunity to assess what features are mission-critical for your needs.

First and foremost, you should evaluate the material composition of the valves. Durable materials like stainless steel or brass can enhance longevity and performance under extreme conditions. Additionally, consider the pressure rating of the valves. Choosing valves that can withstand the specific pressures of your applications will help prevent leaks and failures.

Another important tip is to ensure compatibility with existing systems. Conduct a thorough analysis of your current pipeline and system requirements to select valves that seamlessly integrate. Pay attention to the valve design, as various configurations such as ball, gate, or globe valves serve distinct functions. Acknowledging these factors will empower you to make informed decisions tailored to your business needs.

When sourcing service valves, evaluating their quality and durability is paramount to ensuring optimal performance and reducing long-term costs. According to a report by MarketsandMarkets, the global valve market is expected to reach $96.39 billion by 2025, reflecting an increasing focus on high-performance components that withstand harsh conditions. When assessing quality, look for valves that comply with industry standards such as ANSI or API, as these certifications indicate reliability and adherence to safety protocols.

Durability is another crucial factor, particularly for businesses that operate in high-stress environments. A study by ResearchAndMarkets reveals that service valves made from advanced materials like stainless steel and high-performance plastics have significantly longer life cycles compared to traditional materials. Valves with features such as corrosion resistance and a robust design can endure extreme pressures and temperatures, reducing the frequency of replacements. Investing in high-quality, durable service valves not only enhances operational efficiency but also contributes to a more sustainable business model by minimizing waste and maintenance costs.

| Parameter | Description | Quality Rating | Durability Test Result |

|---|---|---|---|

| Material | Type of material used in manufacturing | A | Passed |

| Pressure Rating | Maximum pressure the valve can handle | B | Passed |

| Temperature Range | Temperature limits for efficient operation | A- | Passed |

| Certifications | Industry certifications achieved by the valve | A+ | Verified |

| Lifespan | Expected operational lifespan of the valve | B+ | Passed |

When sourcing service valves for your business, prioritizing reliable suppliers is crucial to ensuring quality and performance in your operations. Recent industry developments highlight the importance of forging strong relationships within the supply chain. For instance, a leading energy company has formed a decade-long partnership for valve supply and related services, emphasizing collaboration as a key driver for success. This model demonstrates how well-established alliances can lead to more consistent quality and innovation in the products provided.

In addition to building partnerships, businesses should consider market trends and projected growth within specific valve sectors, such as cryogenic valve assemblies, expected to reach a market size of USD 7.21 billion by 2029. Understanding these dynamics can aid in identifying suppliers that not only excel in product quality but are also positioned for future growth. Furthermore, keeping an eye on regulatory changes and industry best practices, such as lead-free requirements for plumbing components, can guide businesses in selecting suppliers that align with both compliance and sustainability goals. By focusing on these aspects when sourcing service valves, companies can optimize their procurement strategies for long-term success.

When selecting service valves for your business, ensuring compliance with industry standards is crucial. The market for PTFE-lined plug valves is projected to reach $64.14 million in 2024, with expectations to grow to $84.01 million by 2032, reflecting a steady CAGR of 3.4%. This growth is indicative of the increasing importance of reliable and compliant components in fluid management systems, particularly in sectors that demand high-performance standards.

In the automotive sector, the market size for passenger car diesel engine exhaust valves is anticipated to exceed $2.8 billion in 2024. The projected compound annual growth rate (CAGR) of 4.9% from 2025 to 2034 is driven by the rising demand for aftermarket services and the aging of diesel fleets. This trend highlights the need for service valves that not only meet basic operational requirements but also comply with stringent emission regulations, ensuring environmental responsibility while maintaining vehicle performance.

As businesses navigate the complexities of sourcing service valves, understanding the market dynamics and the importance of compliance will enable them to make informed decisions. Investing in quality valves that adhere to industry standards will ultimately contribute to operational efficiency and regulatory adherence in the long run.