MENUMENU

In industrial applications, the role of ball valves is becoming increasingly crucial as companies seek efficient and reliable solutions for fluid control. According to a report by MarketsandMarkets, the global ball valve market is projected to grow from USD 9.5 billion in 2020 to USD 12.4 billion by 2025, at a compound annual growth rate (CAGR) of 5.5%. This growth can be attributed to the rising demand for automation across various industries and the need for advanced fluid handling technologies.

In industrial applications, the role of ball valves is becoming increasingly crucial as companies seek efficient and reliable solutions for fluid control. According to a report by MarketsandMarkets, the global ball valve market is projected to grow from USD 9.5 billion in 2020 to USD 12.4 billion by 2025, at a compound annual growth rate (CAGR) of 5.5%. This growth can be attributed to the rising demand for automation across various industries and the need for advanced fluid handling technologies.

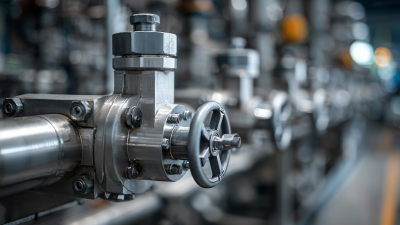

Ball valves, known for their robust construction and excellent sealing capabilities, are essential components in applications ranging from oil and gas to water treatment. As industrial processes evolve, understanding the intricacies of ball valves will be paramount for engineers and decision-makers striving for optimal operational efficiency and compliance with stringent regulatory standards.

Ball valves play a crucial role in industrial fluid control systems, providing a reliable means to regulate the flow of liquids and gases in various applications. Their design features a spherical disc that allows for quick opening and closing, ensuring minimal pressure loss and optimal performance. This efficiency is particularly important in environments where precise flow control is vital, such as oil and gas, chemical processing, and water treatment industries.

Tip: When selecting a ball valve, consider the material compatibility with the fluids it will handle. Many industries utilize different media that can corrode or degrade the valve material over time. Therefore, choosing the right material—such as stainless steel for corrosive substances or plastic for less aggressive fluids—helps ensure the longevity and efficiency of the valve.

Another important factor is the valve size. Oversized valves can lead to unstable flow conditions, while undersized valves may restrict flow and cause pressure buildup. Proper sizing based on system requirements is essential for effective fluid control.

Tip: Regular maintenance of ball valves is key to their reliability. Inspecting seals and seats can prevent leaks and ensure that the valve functions smoothly over time, ultimately saving time and money in operational costs.

| Type of Ball Valve | Material | Size Range (inches) | Pressure Rating (PSI) | Temperature Range (°F) | Typical Applications |

|---|---|---|---|---|---|

| Floating Ball Valve | Brass | 1/4 - 4 | 150 | -20 to 200 | Water, Air, Gas |

| Trunnion Ball Valve | Carbon Steel | 2 - 12 | 600 | -50 to 400 | Oil, Gas, Chemical |

| Full Bore Ball Valve | Stainless Steel | 1 - 6 | 300 | -20 to 250 | Food Processing, Pharmaceutical |

| V-Port Ball Valve | PVC | 1/2 - 3 | 150 | -10 to 140 | Water Treatment, HVAC |

When selecting ball valves for industrial applications, understanding their key characteristics is essential. The materials used in the construction of ball valves play a pivotal role in their performance and durability. Common materials include stainless steel, brass, and PVC, each offering specific advantages depending on the application environment. Stainless steel valves are known for their resistance to corrosion and high temperatures, making them ideal for harsh conditions. In contrast, PVC valves are lightweight and cost-effective, suitable for chemical processing where corrosion resistance is crucial.

When selecting ball valves for industrial applications, understanding their key characteristics is essential. The materials used in the construction of ball valves play a pivotal role in their performance and durability. Common materials include stainless steel, brass, and PVC, each offering specific advantages depending on the application environment. Stainless steel valves are known for their resistance to corrosion and high temperatures, making them ideal for harsh conditions. In contrast, PVC valves are lightweight and cost-effective, suitable for chemical processing where corrosion resistance is crucial.

The design of ball valves is another significant factor influencing their functionality. Typically, a ball valve comprises a spherical disc that rotates within the valve body, controlling the flow of liquid or gas. This simple yet effective design allows for quick open and close operations, making ball valves highly efficient. Additionally, they can feature different designs such as full-bore or reduced-bore, which can impact flow rate and pressure drop. Understanding these design variations and their implications helps engineers choose the right ball valve for their specific industrial needs, ensuring optimal performance and reliability in their systems.

In the realm of industrial applications, understanding the comparative advantages of ball valves versus other valve types is essential for optimizing operations. Ball valves, known for their robust design and reliable performance, provide a significant advantage when it comes to controlling the flow of liquids and gases. Their construction allows for a quick shut-off and minimal pressure drop, making them ideal for critical applications where precision is paramount. Additionally, the use of materials like PTFE in lining these valves enhances their resistance to chemical corrosion, crucial for industries dealing with aggressive substances.

The growing demand for efficient and durable valves can be seen in the rising trends of the valve market. With the global industrial valve market projected to exceed $75.9 billion in 2024 and a compound annual growth rate of 6.6% anticipated until 2034, industries are increasingly shifting towards advanced valve technologies. In particular, the focus on renewable energy projects, especially in solar applications, demands valves that can withstand diverse operational conditions. As countries invest heavily in renewable energy infrastructure, the development and adoption of specialized valves that cater to this shift, such as those used in solar energy systems, highlight the evolving landscape of industrial valve usage.

Maintaining ball valves is crucial for ensuring optimal performance in industrial applications where precision and reliability are key.

According to a report by the Global Valve Market, proper maintenance can enhance a ball valve's lifespan by up to 40%, reducing both downtime and replacement costs. Regular inspections and routine maintenance practices, such as lubrication and part replacements, are essential. Industrial settings should implement a schedule for visual inspections and functional testing to identify wear and tear before they lead to failures.

Furthermore, data from the Valve Manufacturers Association indicates that nearly 30% of valve failures arise from improper maintenance practices. For ball valves, this may include neglecting seal integrity or operating them outside recommended pressure and temperature ranges.

By following manufacturers’ guidelines and investing in training for personnel, companies can significantly decrease the risk of malfunction. The combination of scheduled maintenance and staff education not only enhances valve performance but also ensures compliance with safety regulations, ultimately leading to a more efficient operation.

Ball valves are critical components in a wide range of industrial applications, required to manage the flow of liquids and gases efficiently. The importance of adhering to industry standards and regulations cannot be overstated, as they ensure safety, reliability, and performance. For instance, the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) have established guidelines that directly influence the manufacturing and testing processes of ball valves used in critical industries such as oil and gas, water treatment, and chemical processing.

According to a report by Transparency Market Research, the global ball valve market was valued at approximately $11 billion in 2020, with a projected compound annual growth rate (CAGR) of 7.5% from 2021 to 2028. Compliance with regulations such as the Pressure Equipment Directive (PED) in Europe and the American Petroleum Institute (API) standards in the U.S. is essential for manufacturers aiming to tap into this growing market. These standards demand rigorous testing procedures, including pressure testing and material certification, ensuring that ball valves maintain integrity under high-pressure conditions and extreme temperatures, ultimately safeguarding infrastructure and personnel in industrial environments.